To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-10-22

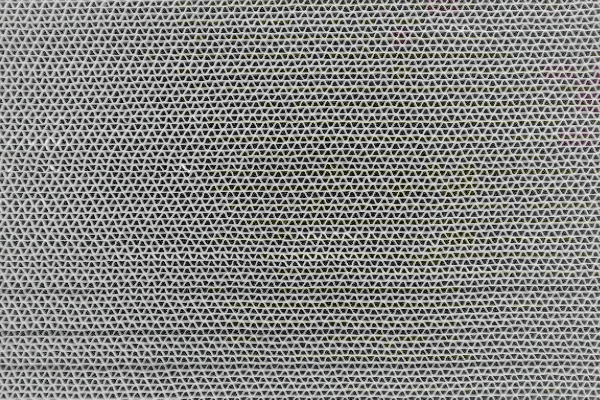

In the operation of laser cutting machines honeycomb tables, the surface state of the honeycomb plays a quiet yet decisive role in how clean and precise the final cut turns out. While settings like laser power and focus often get the spotlight, the platform beneath the material can make just as much difference.

A laser cutting machines honeycomb surface supports the sheet while letting the laser beam pass through the gaps with minimal reflection. But as cutting continues, high heat and molten residue gradually change the surface. Dust, oxides, and burn marks build up over time, and once the surface is uneven or dirty, it directly affects how flat the material sits and how the laser behaves during the cut.

If the honeycomb cells start clogging, air and smoke can’t move freely under the material. Heat lingers longer than it should, sometimes leaving faint burn marks or rough edges. In severe cases, metal residues can reflect stray laser light back onto the workpiece, leading to discoloration or tiny surface burns—especially noticeable when cutting thin or coated materials.

Another issue comes from deformation. A laser cutting machines honeycomb base that has been through countless heating and cooling cycles can warp slightly. Even small changes in flatness shift the laser’s focal distance, which leads to uneven cuts or incomplete penetration. The result is extra polishing or even remaking parts that should have been perfect the first time.

Regular upkeep helps prevent these problems. Cleaning the honeycomb gently, clearing residue between the cells, and replacing panels that have become uneven all help keep the system stable. For workshops using laser cutting machines honeycomb tables every day, keeping a simple maintenance routine can make the difference between average and consistently sharp results.

In short, the honeycomb surface is not just a background part of the process—it shapes the quality of every edge. A clean, even, and well-maintained laser cutting machines honeycomb platform supports smoother cutting, better finishes, and a longer life for both the machine and its component