To be a valuable global supplier

for metallic honeycombs and turbine parts

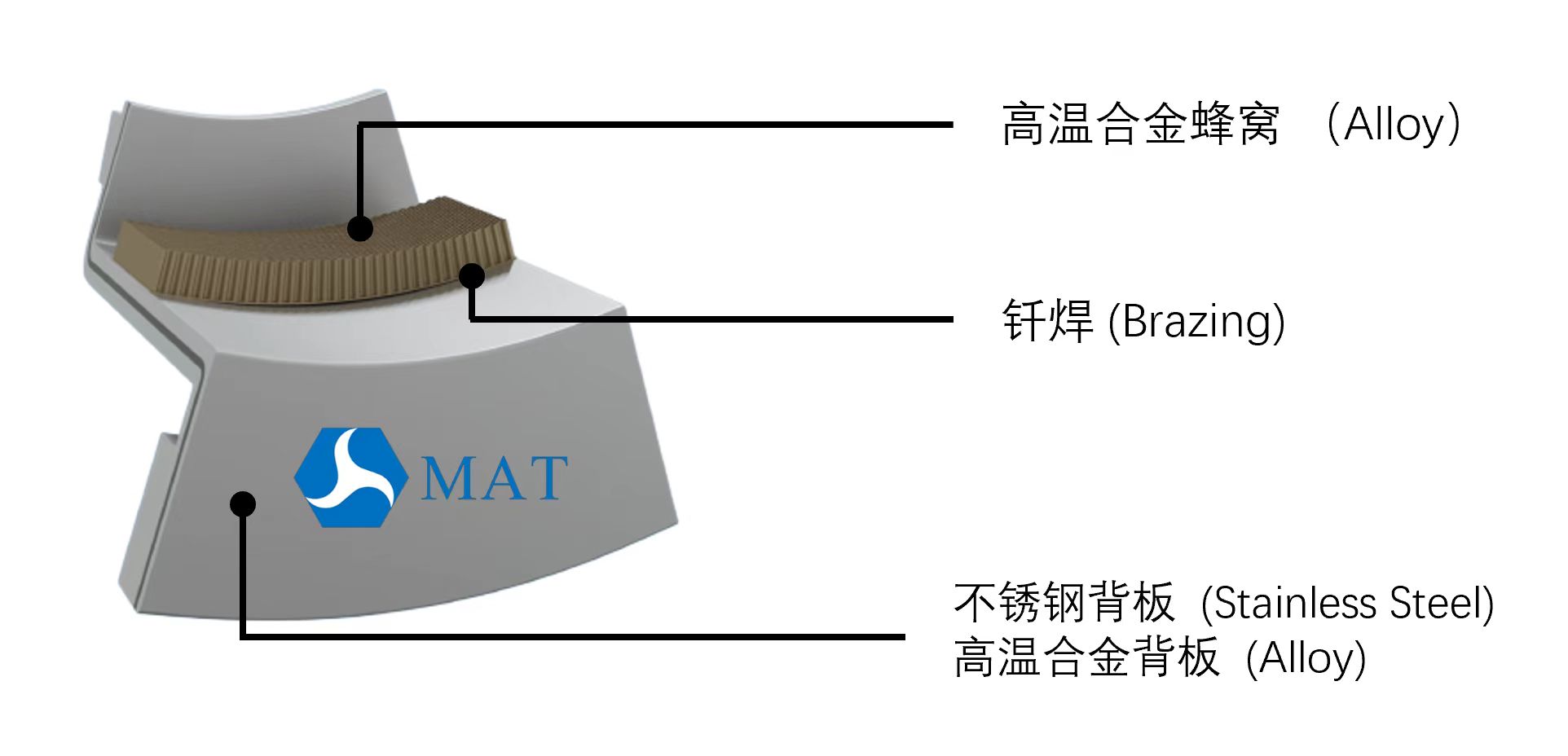

The honeycomb seal is brazed by the back plate (a base plate facing the casing wall) and the metallic honeycomb (a brush cross-section facing the tip of the turbine rotor blade), which effectively reduces the air path gap between the rotating parts, while increasing the efficiency of the engine. Therefore, it is widely used in the cold and hot ends of gas turbines and aero-engines.

At the same time, honeycomb is mostly used as rotor blade end seals (friction seals, wear-resistant seals, etc.) for two main reasons:

(1) Provide gas path seals to prevent engines’ hot gases from bypassing the ends of the turbine rotor blades;

(2) Provide a sacrificial surface on which the rapidly rotating blade will rub.

When achieved, the fuel efficiency will be higher and service life of all rotating components will be longer.

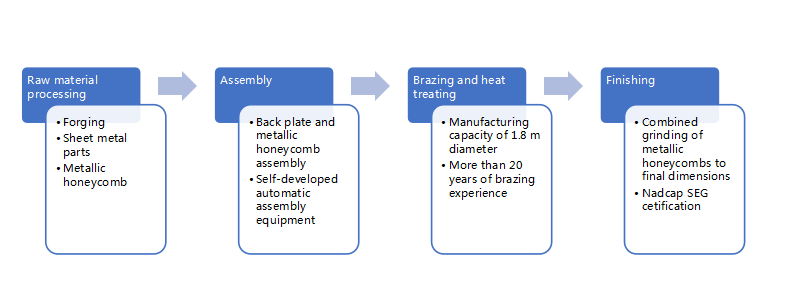

MAT Aviation can manufacture honeycomb seals composed of metallic honeycombs and back plates of different materials according to customers’ requirements, and provide one-stop service.

1. Cell size of honeycomb:

0.8 mm to 3.2 mm

2. Selection of backplane:

Segment, ring;

Castings, forgings, metal plates

3. Brazing process of honeycomb and backplate based on different metal materials