To be a valuable global supplier

for metallic honeycombs and turbine parts

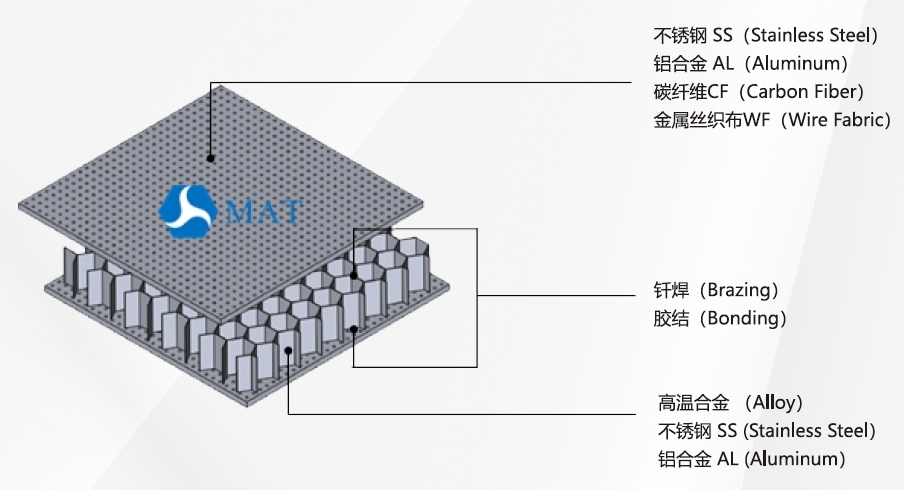

With the rapid development of industry, while bringing great convenience to people's life, the noise problem has caused serious environmental pollution. Reduce noise pollution is a necessity for the development. MAT brazes or glues the metallic honeycomb and the porous plate to produce a special honeycomb plate to reduce noise. The principle is based on the special properties of the metallic honeycomb, by absorbing external shocks and transforming them into deformation energy of the core material, and then releasing them slowly. At the same time, when the sound wave enters the metallic honeycomb, it will cause the vibration of the air and the material. Due to the frictional resistance and viscous resistance, part of the sound energy will be converted into heat energy and dissipated, thus playing the role of noise reduction.

MAT has more than 5 years of experience in honeycomb manufacturing and brazing, which enable us to meet the needs of different customers for noise reduction through the combination of different materials and manufacturing methods.

Compared with other materials, noise reduction panels with metallic honeycomb structure have the advantages of light weight, high stiffness-to-mass ratio, good moisture-proof, fire-proof performance, and ductility, which is widely used in aviation, navigation, railway, automobile, construction and other industries.

The aviation industry has strict noise reduction requirements, and manufacturers are striving to find efficient solutions to reduce noise pollution to improve passengers’ comfort level. As we all know, the engine is the main source of aircraft noise, and the acoustic liner in the anechoic nacelle is one of the most promising noise reduction technologies. Considering that the honeycomb structure has the advantages of light weight, high strength, high rigidity, good stability, good sound insulation and noise reduction effects, especially in the high frequency band, it not only saves space but also reduces weight. As a result, the honeycomb structure has been rapidly and widely used in aero-engines.

The metallic honeycomb acoustic liner manufactured by MAT not only has the advantages of high rigidity-to-mass ratio, good sound absorption and noise reduction performance, etc., we also have patents such as "flexible honeycomb design and manufacturing technology" with independent intellectual property rights, which can complete the manufacturing of acoustic liner more effectively to meet the development and noise reduction needs of the aviation industry.