To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-11-25

In any combustion-based engine—gasoline, diesel, or industrial gas—the exhaust stream carries a mix of pollutants: CO, unburned hydrocarbons, and different forms of nitrogen oxides. A Purification Catalytic Converter is the component responsible for turning these into CO₂, H₂O, and harmless nitrogen before the gas leaves the tailpipe.

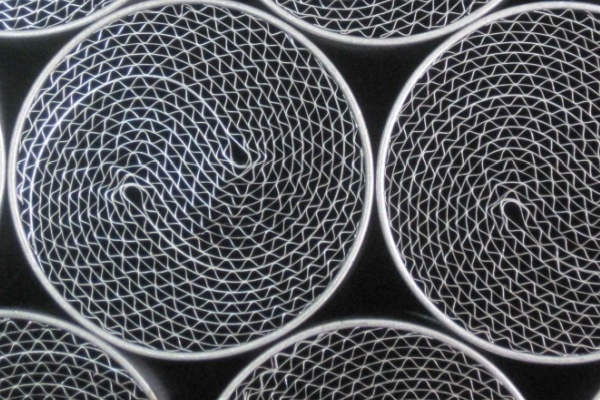

From the outside, a converter can look simple: a canister welded into the exhaust line. What actually does the work sits inside—a honeycomb substrate coated with an active catalytic layer.

Most converters today use either a ceramic monolith or a metal honeycomb core. Both rely on the same idea:

create hundreds of tiny channels so exhaust gas stays in contact with the catalytic coating long enough for reactions to happen.

Inside the substrate, the metal or ceramic is coated with a washcoat loaded with precious metals like platinum, palladium, and rhodium. This coating provides the surface area where CO, HC, and NOx are converted chemically.

Although ceramic versions are still common in gasoline vehicles, metal substrates are often preferred for diesel and industrial applications because they heat up faster and handle vibration better.

A Purification Catalytic Converter doesn’t “filter” pollutants—it changes them chemically.

The main reactions are:

CO + O₂ → CO₂

This is the easiest reaction and happens as soon as the catalyst reaches light-off temperature.

Unburned hydrocarbons + O₂ → CO₂ + H₂O

HC molecules need more temperature and surface area, which is why substrate geometry matters.

NO + CO → ½N₂ + CO₂

Gasoline engines run near stoichiometric conditions, so NOx, CO, and HC can all be handled at once.

Diesel engines operate lean (excess oxygen), so NOx reduction cannot happen inside a standard Purification Catalytic Converter.

Diesel systems rely on a DOC + SCR arrangement instead.

Although both are “Purification Catalytic Converters,” their jobs are not the same.

Used on gasoline engines

Handles CO, HC, and NOx

Requires tight air-fuel ratio control

Works best between 350–800°C

A type of Purification Catalytic Converter used in diesel engines

Converts CO and HC

Converts organic fractions in PM

Helps generate NO₂ for downstream DPF

Designed for lower and more variable exhaust temperatures

Diesel converters cannot reduce NOx directly, which is why SCR systems or EGR are added.

A Purification Catalytic Converter only performs as well as the substrate inside it. Engineers usually evaluate:

Channel density (CPSI): more channels mean more surface area but higher pressure drop.

Foil or wall thickness: affects heat-up speed and vibration resistance.

Material: metal substrates handle thermal shock and vibration better than ceramic.

Geometry: round and oval shapes are used to match installation requirements and durability needs.

A well-matched converter reaches light-off quickly and maintains stable conversion even under load changes.

In real projects, a Purification Catalytic Converter isn’t chosen in isolation. Its size and substrate volume are matched to:

engine displacement

exhaust flow rate

expected temperature window

vibration conditions

emission regulations

For example:

A small stationary engine may run at a steady temperature, making ceramic suitable.

A construction machine sees shock, vibration, and cold-hot cycles, making metal honeycomb a better choice.

Even with electrification on the rise, engines for logistics, marine, backup power, mining, and heavy equipment will continue needing reliable emission systems. The Purification Catalytic Converter remains the first line of defense—turning harmful gases into safe ones, keeping equipment compliant without major changes to the engine itself.