To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-10-25

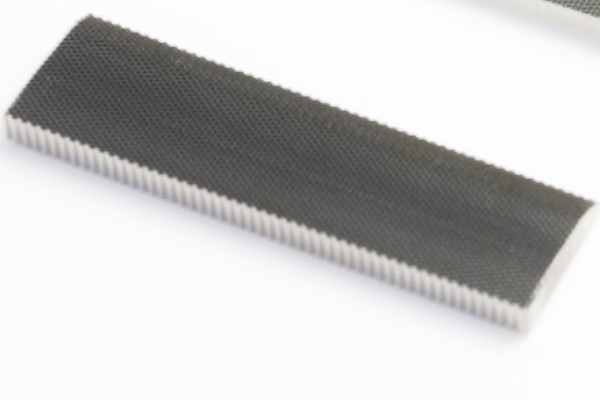

Anyone who has spent time working with Laser cutting machines honeycomb tables knows how much vibration can mess up a clean cut. A little shake in the setup, or a small movement in the workpiece, can cause rough edges or alignment issues. That’s where the honeycomb platform earns its keep — it helps absorb those small vibrations and keeps the material steady.

The honeycomb structure isn’t just for looks. Its grid spreads out pressure evenly, so when the laser head moves fast or the heat from cutting makes the sheet expand a little, the part stays flat instead of shifting. This setup is especially useful when you’re cutting thin stainless, acrylic, or any flexible material where even a tiny movement shows up in the result.

Another thing people sometimes miss is how the Laser cutting machines honeycomb platform helps air and smoke move through the table. When the fumes or air pressure can’t escape, the material can lift slightly and cause the laser to lose focus. With a clean honeycomb surface, the air passes smoothly, and the laser stays sharp and consistent across the whole sheet.

If you’ve been running your machine for a while, you might notice small marks or residue building up on the honeycomb. That’s a sign it’s time to clean it. Even a bit of stuck material can throw off the balance and add tiny vibrations. Keeping the Laser cutting machines honeycomb surface clear makes a big difference in how stable and accurate your cuts stay.

In the end, the honeycomb table isn’t just another part of the setup — it’s one of the reasons precision cutting works as well as it does. If you want reliable accuracy and smooth results, taking care of your Laser cutting machines honeycomb platform is just as important as tuning the laser itself.