To be a valuable global supplier

for metallic honeycombs and turbine parts

Release time:2025-11-11

When the new Euro VI and EPA standards came in, most of us in the diesel world knew things were about to get tighter. Emission limits are not forgiving anymore, especially for NOx and hydrocarbons. To meet those numbers, the Diesel Oxidation Catalyst — the DOC — became one of the main parts we had to get right. And inside that DOC, the DOC metal substrate is what really decides how well the whole system works.

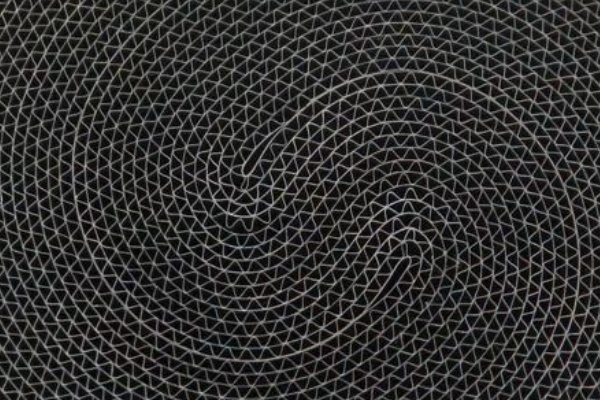

We’ve worked with different substrate types over the years, and metal ones have proven the most reliable for heavy-duty use. They handle heat and vibration better than ceramic. The thin stainless or FeCrAl foils are rolled into a honeycomb shape, giving plenty of surface for the coating but still letting exhaust flow through freely. Getting that balance right — between surface area and back pressure — takes a lot of testing.

In cold start conditions, the DOC needs to light off as soon as possible. That’s where the substrate design matters most. Thinner walls and higher cell density help it reach temperature faster, which means CO and HC are converted earlier. In a lab, that looks simple, but on real engines — especially in trucks or construction machines — temperature swings can be brutal. One minute it’s idling at 150°C, the next it’s at 700°C on a hill climb. The substrate must survive that without the coating cracking or peeling.

We’ve seen older stainless types lose performance after just a few hundred hours because of oxidation. The newer FeCrAl materials handle it much better. They hold the washcoat longer and keep flow resistance stable even after long endurance runs. That stability is what helps engines consistently pass Euro VI and EPA cycles.

Another thing we pay attention to is flow distribution. If the DOC metal substrate geometry isn’t designed properly, gases won’t spread evenly, and we end up with hot spots or back pressure build-up. That doesn’t just hurt performance — it affects the DPF right after the DOC. A good DOC substrate also helps oxidize some NO into NO₂, which makes DPF regeneration smoother. When that balance is right, the whole system breathes easier.

We’ve also tested different open-area ratios. Sometimes a slightly higher open area — meaning a bit less dense honeycomb — can be more stable in off-road engines or machines that don’t run at steady RPMs. It might sacrifice a bit of conversion efficiency, but it pays off in durability and long-term reliability.

At the end of the day, meeting these emission standards isn’t about adding more catalyst or sensors. It’s about smart, steady design. The might look like a simple rolled-up foil, but every small change — wall thickness, channel shape, coating quality — changes the system behavior. Those of us who’ve tuned engines or replaced failed DOCs in the field know this the hard way.

So when we talk about Euro VI or EPA compliance, I’d say the DOC metal substrate is where it really begins. Get that part right, and everything downstream — DPF, SCR, ASC — will do its job a lot better.